"Split"

It's all cast now. Getting there.

Bread and Tony Lama's.

Cutting bread.

I thought that I was going to mold this first and then cut the new wax up in "slices" for casting but to save a tremendous amount of time, energy, and effort, I've decided to cut the original wax model and cast it directly with no backup mold. This is a bit of a risk because if something happens to the wax or the ceramic investment mold along the way or if the bronze breaks out of the mold during casting, then I lose the piece entirely and I would have to start from scratch again. Risks: sometimes they work, sometimes not. That's life. Onward.

Freshly sealed...

...and ready for the kiln. The axe handle for "Split" with it's final ceramic coat is ready to be put into the kiln for firing and melting the wax out of the mold.

Four halves of the axe

The axe handle of "Split" is invested in four sections with the first 2 layers of fine ceramic. I will add one more fine coat for detail and then the coarser ceramic will be added for building up the layers of the mold. Once this has upward to 8-12 coats, it will be ready to expose the wax by breaking off the top layer of the 'cup'. The mold will then be placed in an open bottom kiln upside down and fired. At the same time the ceramic is being fired, the wax is melting and evacuating the mold which is collected in a water bath below the kiln. When the wax is completely burned out, it is buried in a sand pit and ready to accept the molten bronze.

Split is split

Split is split...at least in wax.

Bathing with sculpture

Sometimes taking a warm bath with your sculpture is part of the process. After making wax copies of the axe handle, I took them home to bend in the bath. We are both clean now. Incidentally, this is how I bent the wax with "Tusk" as well.

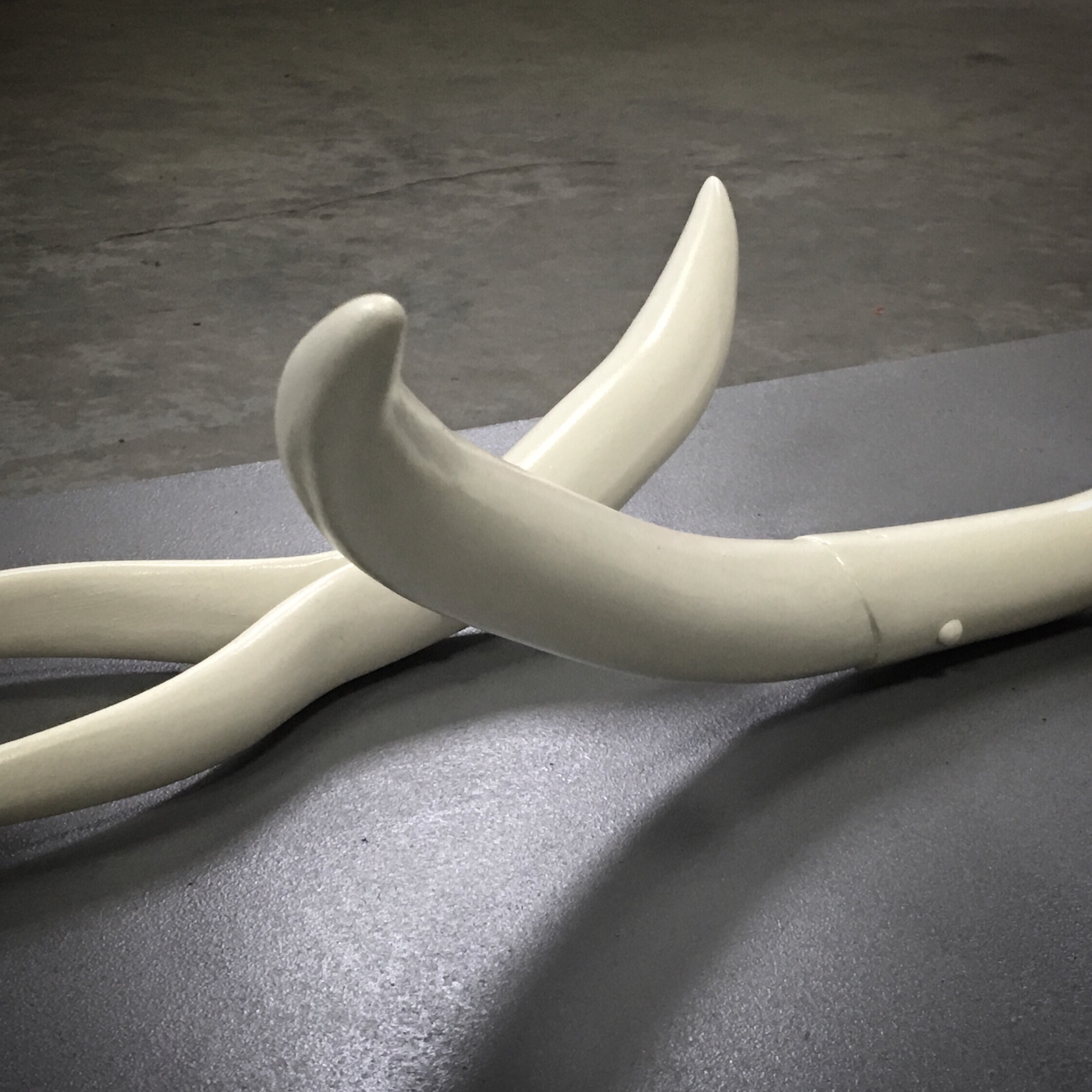

More Tusk from the Rover 2016 exhibition in Brooklyn.

Tusk. Enameled bronze, 2016

Molding the axe handle for "Split"

The first side is complete and now I'm about to start the second side. It begins with a couple of coats of brushable rubber and once that cures, It will be covered with a plaster shell to hold the shape.

Tusk gets a base

Well-- I was thinking about painting a grey rectangle on the wall and hanging Tusk but I went with a base. I think I made the correct choice although I have been known to change my mind. Pretty much done (except the temp enamel finish). I will strip this in a few weeks and send it to the powder coaters for the same color/finish- except more durable and permanent.

Suspended

Tusk! Cast bronze and suspended- all 21 1/2 lbs- at least until the enamel dries. I drilled the holes and left the 8 rivets out so this could be done (painting and powder coating). I'm showing this in a few days and the powder coaters need more time, so I've put my own ivory enamel on (for now) and after the show I will sandblast this off and get the permanent ivory powder coat surface. The rivets will be done separately.

Bronze is sometimes too shiny.

Before I put a more permanent, and costly powder coated finish on Tusk, I sprayed it down with spray paint to see the surface flaws a little better. They are very hard to see on shiny metal. So- the sculpture took the weekend off from the city and traveled with me to the hills. I will then sand and fix the flaws before stripping the paint back off with lacquer thinner and sand blasting.

Actually...

With a little sanding, I think I like it the way it is.

Etched...

Axe head for "Split". Etching this hardened steel proved more difficult than I thought. I do have a nice ghost text that seems a bit aged. I might keep it or etch it again with offset, overlapping letters.

Wood in waiting.

I cut this wood up after a storm that downed 15 trees about 3 years ago. So far, I have found use for 3 of the blocks: the 2 bases for "Trunk" and the carved bread loaf for "Bread". This wood is seasoned and waiting. It's good to plan ahead for future supplies!

Into the acid

A part of "Split" is about to be etched.

Revisiting a statement I wrote last April...

I am asked a lot why do I put every bit of my time, effort, and resources, into making a sculpture if it's not a commission? Why do I push myself to exhaustion? Why do I skip meals, bloody my hands, kill my back, and ignore the pain so that I can get just a little more done? I could answer something like I don't really have a choice, or that if I don't, I wouldn't be true to who I am. People who have callings might give you a story of how that happened. Why they chose a way of life-- why they transcribed the music in their heads--why they devoted themselves to God -- Why they followed their hearts instead of their logic-- Why they took a risk when every bit of their fiber told them to stay in safety. Maybe there was a bright light or an understanding. Maybe they were completely at their lowest when something or someone showed them the way to higher ground. An epiphany? Maybe I would tell you that for me, each piece that comes to me through some inspiration, a spark within the instant, a late summer's dream, a random and extraordinary meeting, the fragrance of a long forgotten perfume, a memory not exactly mine, is like a calling: instructions to unravel a little bit of myself, my surroundings, the universe. I do it because it drives me. It feeds my soul and passion. It is my looking glass into the past, present, and future. I drink because I am thirsty.

Tusk. I heated and pressed the bend slightly in. It was too dramatically curved but I think I'm happy with the slight curve now. I also took the grinder to the cast rivets and drilled holes for new rivets. I need the holes so that the powder coaters have a way to hang the piece for the process. I'll powder coat the rivets separately and then put them in afterwards.

Chasing Tusk

I worked again on Tusk this evening, chasing the welds and trying to get the piece ready for powder costing. I'm not sure if I like the curve totally yet. I might heat the bronze with a torch and press the curve out a little. Looking from the top it curves more than I like. This photo here looks a lot better at this angle and doesn't show that extreme curve.